Fujikin Singapore

Bio-Pharma, Food & Beverage Valves

- Bio-Pharma, Food

& Beverage Valves - BNW Series

Weir Diaphragm Valves - LPS Valves

Weirless Diaphragm - By Series

Angle Seat Valves - BPV Sanitary

Pinch Valves

BNW Series Weir Diaphragm Valves

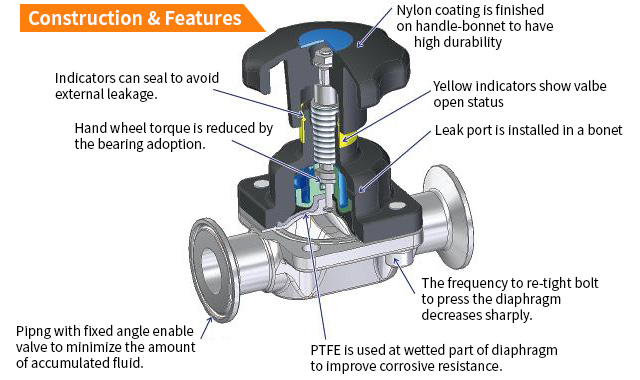

Manual Operation

- Since there are few pockets in the wetted part and it is streamlined, the flow path resistance is small and the structure is such that process fluid and cleaning liquid do not remain easily, so it is a valve suitable for cleanliness and sterility.

- Because there is no gland part, it is more reliable against leakage than valves with other gland parts.

- The diaphragm has a structure that prevents internal and external leakage.

- 2011 Received the 8th Super Manufacturing Parts Award Encouragement Award.

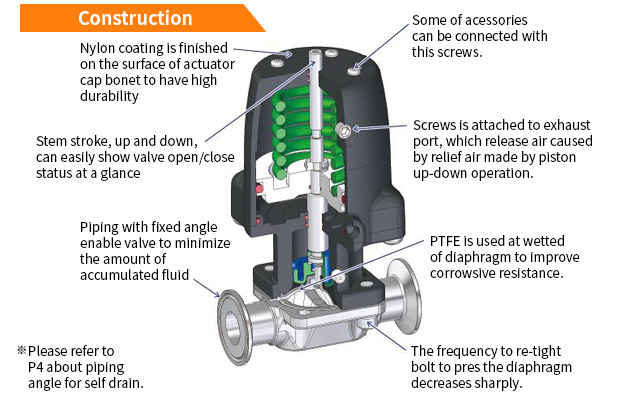

Automatic Operation

- There are three types of actuator actuation methods: spring back type (normally closed, normally open) and double action

-

The actuator supply port connection size is

8A to 50A (2S): Rc1/8

65A (2.5S) to 100A (4S): Rc1/4 - Screw holes for mounting accessories are provided at the top. Various accessories such as limit switches, proximity switches, and opening adjustment mechanisms can be retrofitted.

- 2011 Received the 8th Super Manufacturing Parts Award Encouragement Award.

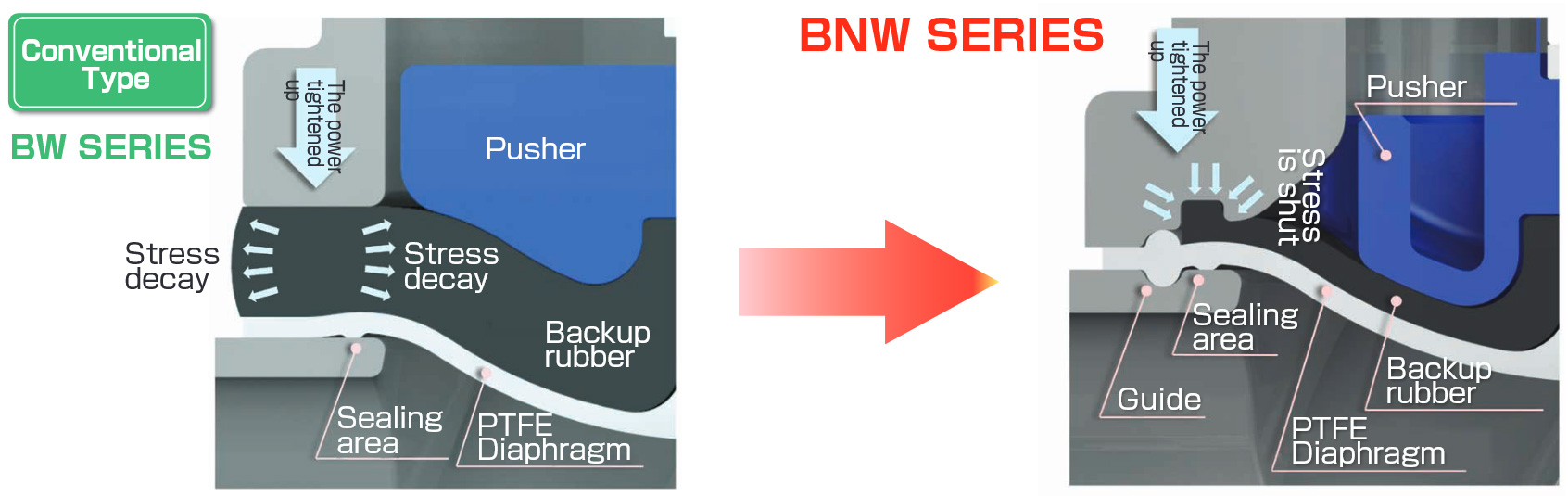

Sealing Construction

- Conventional Type: Thick back up rubber can compensate for production variation of the body. However, the thick rubber often become slack due to long term use.

- BNW Series: Diaphragm has two touchlines (projection). The outer line serves as a guide for body and actuator while the inner line serves as a seal. This construction will not have rubber slack caused by long term use.

- Sealing is maintained during thermal cycling under constant steam of 150°C, the valves can withstand up to 100,000 cycles before replacement or re-torquing is necessary.

- Even when attached to a pipe, it can be easily disassembled in this way by loosening the hexagon socket head cap screw.

- Actuator (operation part)

- Diaphragm

- Body

Need more informaton?

Download the catalogue or

reach out to us by completing the form.

Download the catalogue or

reach out to us by completing the form.