Fujikin Singapore

Introduction to Angle Seat Valves

Introduction to Angle Seat Valves

An angle seat valve is a pneumatically-controlled valve with a piston actuator providing linear actuation to lift a seal off its seat. The seat is set at an angle to provide the maximum possible flow when unseated. Due to the angled arrangement of the valve actuators in relation to the pipeline, the compact angle seat on-off and control valves can be installed and operated even in very confined spaces.

By Series Angle Seat Valves

Angle Seat Valves

- Durability with steam is higher than ball valve.

- Smooth flow of fluid is realized.

- Gland structure by know how of high temperature and high pressure valve manufacturing.

- Stable seat performance is realized by caulking method disc packing.

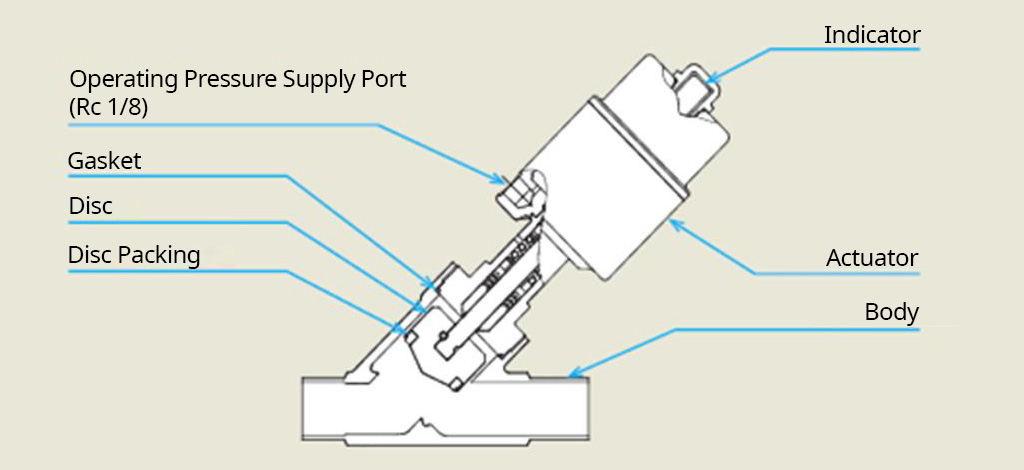

Overview of Basic Structure

The actuator acan rotate 360°, the direction of the operating pressure supply port can be adjusted.

To prevent scratches, the planar part for spanners is not installed on the actuator.

Please hold and rotated the actuator with both hands.

Selection of Valve Type

Please select when fluid is steam or gas. The actuator size can be suppressed compactly and cost reduction is possible. If the fluid is liquid, please be aware that a water hammer may occur when the valve is closed and surrounding equipment may be damaged.

Please select when fluid is liquid. It is also available for steam or gas.

Why use Angle Seat Valves?

Angle seat valves are the ideal solution for boiler manufacturers, temperature control, hygienic applications or hot water systems, thus making them suitable for use in the biopharmaceutical industry, food and beverage processing, chemical processing, personal care applications such as cosmetics and more. Specific usage areas can include switches in automatic control systems, industrial compressors, steam applications, printers and paint dispensers, water treatment machines, bottling and dispensing machines, washing and laundry machines etc. Because the seat has been positioned at an angle such that there’s no flow restriction when opened, the valve is suitable for use with high viscous fluids. It is also ideal for use with high-temperature media or where differential pressure is low.

Design features

Angle seat valves feature robust designs for an extended life cycle and smooth operation. The angle seat valve is piston operated and can feature a closure spring. The valve seat gets positioned at an angle for a restriction-less flow upon being unplugged. A high-pressure pilot medium (compressed air, water, oil) in a cylinder is used to exert pressure on the valve actuator.

Angle seat valves feature large pistons for more output pressure. The pistons usually multiply the input force. And the large-sized pistons are suitable where the air supply is very low to generate necessary force with less input force. Angle seat valves also feature improved sealing to keep off emissions and prolong the media life.

The actuator head on the BY Series Angle Seat Valve can be rotated 360° to allow optimum position of air and electric lines in tight locations. The valve body is generally made of brass or stainless steel, allowing angle seat valves to be applied in hazardous working environments. Connection types include threaded, clamped or welded. Typically, a visual indicator on the top of the piston shows whether the valve is open or closed.

Angle seat valves are an economical option while providing a longer service life. The main advantage of the angle seat configuration is that compared with other valve types it gives a high flow rate with low pressure loss. Other benefits include elimination of water hammer and also resistance to back flow.

If you'd like to find out more and are looking for experienced professionals in the design and manufacturing industry, you may contact Fujikin Singapore at enquiry@fujikin.com.sg or at +65 6848 5760.