Fujikin Singapore

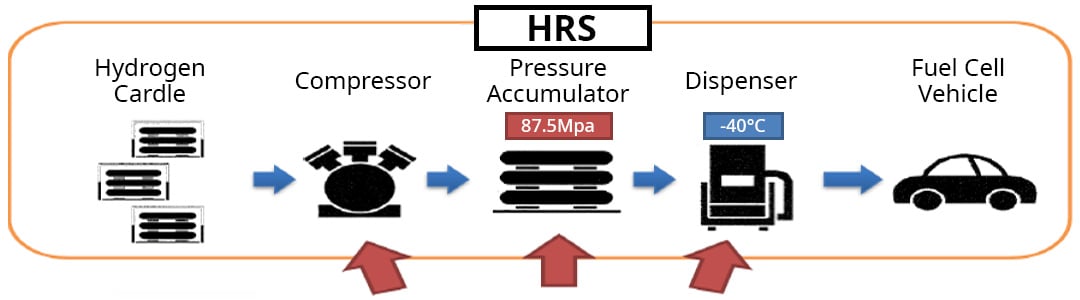

Hydrogen? Contribution

and Safety Fuel Cell Vehicles (FCV)

and Transport High-Pressure

Products Applications Fujikin's

Achievements

High-Pressure Products Applications

1. Control Valve

| Parts | Materials |

|---|---|

| Body | SUS316+Co base alloy |

| Seat | SUS316+Co base alloy |

| Stem | SUS316+Co base alloy |

| Gland Packing | PVDF+PFA |

| Packing Gland Brush | SUS304 |

Fujikin Control valve was developed especially for meeting the specifications for the hydrogen station. Various developments such as:

- Consideration of material.

- The development of valve anticipating the revising of regulations.

- The development of control valve that can apply to communications fuelling for the reduction of fuelling time to the vehicle.

- The development of tube fitting and auto welding which has improved its reliability and maintainability.

- Fujikin has achieved to develop a compact model valve, and the improvement of maintainability by conducting evaluations.

| Cv Value Menu | ||

|---|---|---|

| Rated Cv Value (Max) | Range Ability | Characteristics |

| 0.25 | 100:1 | EQ% or Linear |

| 0.15 | ||

| 0.1 | ||

| 0.07 | ||

| 0.05 | ||

| 0.035 | ||

| 0.025 | ||

| 0.015 | ||

| 0.01 | ||

Excellent Flow controllability

Accessories for Automatic Valve

Regulators with filter

Features

1. Regulating required air supply pressure for flow control valve

| Makers | SSS Co., Ltd. | |

|---|---|---|

| Model No. | XR-108 | |

| Specifications | Air Connecting Port | Rc1/4 (Pressure Gauge: Rc1/8) |

| Filter Element | Polyprene bonded material Element: 5 µm |

|

| Max Supply Pressure | 0.9 MPa | |

| Weight | 0.26 Kg | |

Solenoid Valve

| Explosion Proof Construction | Item Numbers | Types | Makers | Features |

|---|---|---|---|---|

| ExdIICT6 | MOOU-8-E22POA-SA | — | KANEKO SANGYO CO., LTD |

|

| Ex e mb IIC | WBLPG551A005MS | Direct Mount Type 3-Way | ASCO JAPAN CP., LTD |

|

| WBLPG551A017MS | Direct Mount Type 4-Way | |||

| WBLPG551A001MS | NAMUR Type 3,4-Way | |||

| Ex ia IIC T4 | CFSCISG551C505MO | Direct Mount Type 3-Way | ASCO JAPAN CP., LTD |

|

| CFSCISG551C517MO | Direct Mount Type 4-Way | |||

| CFSCISG551C501MO | NAMUR Type 3,4-Way |

*When ordering, please specify explosion-proof construction and power supply specification.

Proximity switch, controller

Features

1. Output electrical signals indicating open or close status of valves.

2. Use a two wire DC system to allow for long distance wiring highly resistant to noise.

| Makers | Model No. IDEC Corporation | Explosion-proof Construction |

|---|---|---|

| Proximity switch | Bi2-G12-Y1 | ExiaIICT6 |

| Controller | IM1-12EX-R | [Exia]IIC |

Explosion proof accessories for Positioner

Intrinsially Safe Explosion Proof Barrer for E32M3 Series

| Makers | Model No. | Explosion-proof Construction |

|---|---|---|

| P & F | KFD2-SCD-Ex1.LK | Exia IIC |

Cable Gland for E53M3 (Explosion Proof) Series

| Makers | Model No. | Explosion-proof Construction | Connecting Threads |

|---|---|---|---|

| Shimada Elctric Co., Ltd | EXBM-16R-* | Exd IIC | 1/2 NPT |

*Please let us know the outer diameter of the cable to be used.

E53M3 (Explosion Proof) Electrical Wiring Closure Plug

| Makers | Model No. | Connecting Threads |

|---|---|---|

| Shimada Elctric Co., Ltd | SBP-16-1/2NPT | 1/2 NPT |

(2) Shut-off Valve

99.9 MPa Shut-off Valves (High Cv Value Type)

| Parts | Materials |

|---|---|

| Body | SUS316+Co base alloy |

| Disc | SUH660 |

| Gland Packing | PVDF+PFA |

| Actuator | A5056 (amongst others) |

Features

- Full-bore type [accommodates port diameter equal to or greater than the inner diameter of 14.2 (40,000psi) size (ø6.35)]

- No usage restrictions on flow direction and differential Pressure

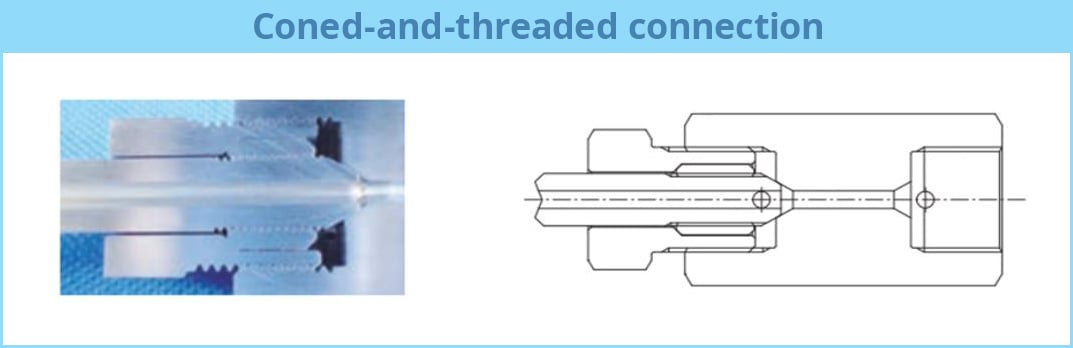

- Connection: Cone and Thread Fitting.

Shut-off Valve (Low temperature type)

| Parts | Materials |

|---|---|

| Body | XM 19 |

| Disc | SUH660 |

| Actuator | A5056 (amongst others) |

Features

- Valve for Hydrogen station uses

- Design Pressure: 99.9 MPa

- Design Temperature: 253 to 50°C

- Japan Technology award 2019

(3) High Pressure Manual Valve

99.9 MPa Compact Manual Valves (Needle Valves)

60,000 psi Type(Nominal Diameter:6.35,9.52)

40,000 psi Type(Nominal Diameter:14.2)

| Parts | Materials |

|---|---|

| Body | SUS316+Co base alloy |

| Disc | SUH660 |

| Stem | SUS316 |

| Gland Packing | PVDF+PFA |

| Gland Nut | SUS316 |

| Handle | ADC12 |

Features

- Compact and with Durable Manual Valves

- With Lock Nut

(4) Check Valve

99.9 MPa Line Check Valves

60,000 psi Type (40,000 psi Type can also be manufactured.)

| Parts | Materials |

|---|---|

| Body A | SUS316+Co base alloy |

| Body B | SUS316+Co base alloy |

| Disc | SUS316 |

| Spring | SUS316 |

Features

- Compact, in line type

- Little pressure drop due to optimal flow pass

Specifications

| Design Pressure | 50MPa |

| Design Temperature | 85°C |

| Fluid Temperature Range | -40 to +85°C |

| Cracking Pressure | Max of 6.86 kPa |

| Range of Use Differential Pressure (Counter Pressure) | Min of 10 MPa |

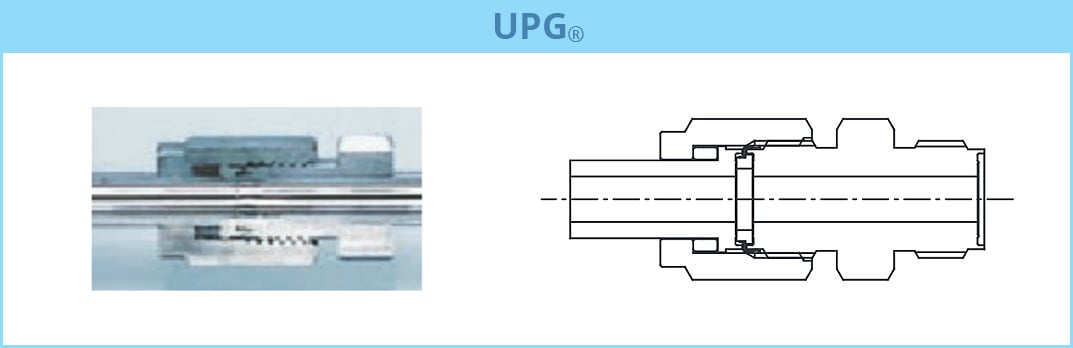

(5) High Pressure Fittings (UPG)

High Performance Metal Gasket Fittings for Ultra High Pressure Hydrogen Gas

| Parts | Materials |

|---|---|

| Body | SUS316+Co base alloy |

| Nut | ASTM A276 316 |

| Collar | ASTM A276 316 |

| *For Norminal diameter 14.2, we uses JIS-compliant materials | |

Features

1. Excellent Air Tightness

- The unique seal structure realizes excellent airtightness.

- Metal gasket type with small load on pressure resistant parts even when detaching is repeated.

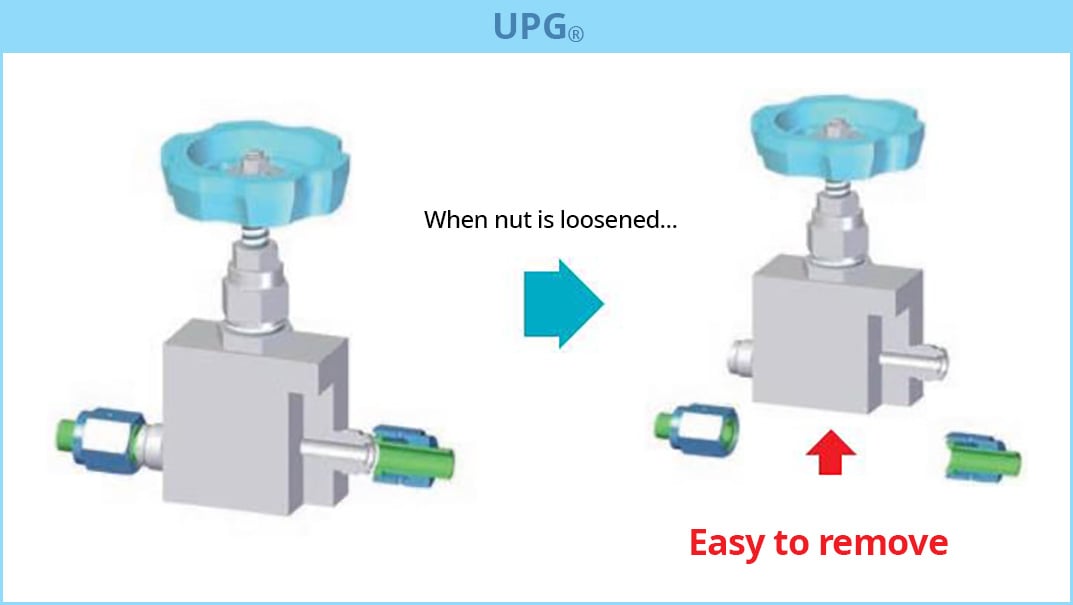

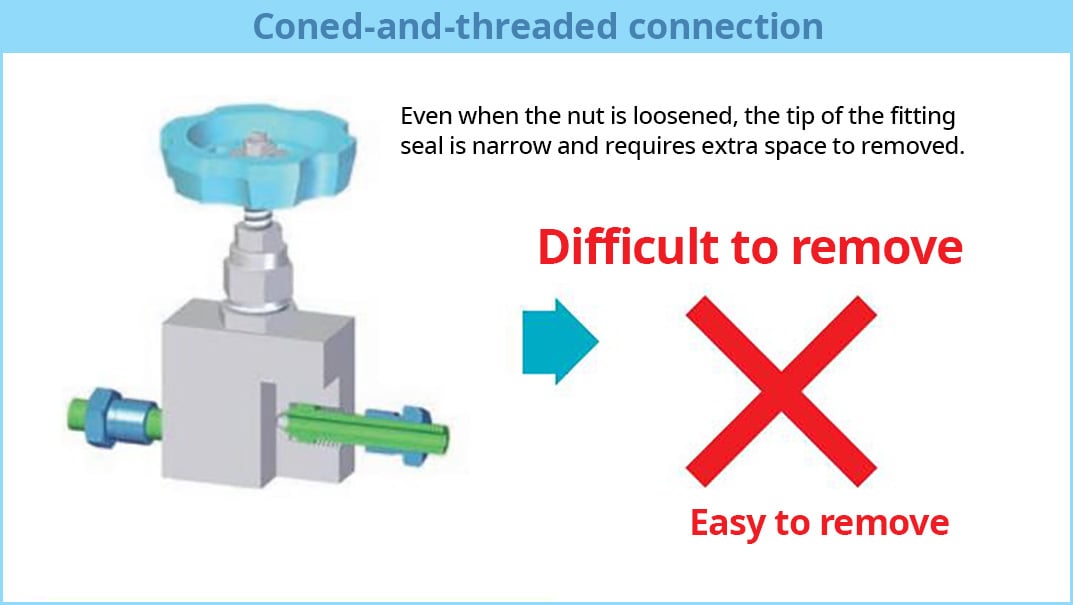

2. Excellent Installation and Operability/Removing

- No need for an axial space for detaching the device.

- Construction instructions include rotation control and overtightening prevention mechanism.

- Compared to coned and threaded joint, construction with low torque can be done.

Creativity of UPG High Pressure Fittings

3. Excellent Scalability

- Excellent vibration proof is achieved by separating the part to be sealed and the part receiving the external force.

- Lineup includes two pressure series: 95 MPa and 50 MPa

| No. | Items | Existing Technology Cone & Thread Fittings | Existing Technology Metal Gasket Fittings for Semiconductors | Metal Gasket Fittings for Ultra High-Pressure Hydrogen Gas |

|---|---|---|---|---|

| 1 | Seal Performance ( 82MPa ) |

ᐃ 99.9MPA Specification However, it is affected by the construction performance and sealing in unstable |

ᐃ 21.5MPa Specification | ⵔ 95MPa Specification Optimum value to maintain pressure ressistance comes from the coefficient of the fitting's inner diameter, diameter of the sealing surface protuberance and the gasket's inner/outer diameter, the sealing portion was devised. |

| 2 | Pressure Resistance ( 82MPa × 1.5 ) |

ⵔ | × (Diagram 4) The seal begins to separate from the gasket at 41MPa |

ⵔ (Diagram 5) |

| 3 | Construction Performance | × Tube threading and additional work on the tip is required |

ⵔ Additional processing is not required on the fitting parts |

ⵔ Same as left |

| 4 | Measures to prevent tubing circulation during construction | × No co-rotation countermeasure |

ᐃ A ball bearing is inserted in the nut, however it is unsuitable for the high load and corrosion resistance required in outdoor use |

ⵔ The nut's bearing is changed to a thrust bearing, which improves the high load and corrosion ressistance |

| 5 | Attachment / Detachment Durability | × Repeated attaching / detaching and the sealing surface deteriorates |

ⵔ When replacing the gasket, the health of the sealing surface in maintained |

ⵔ Same as left |

| 6 | Removability | × Space is required to remove the tube during attachment / detachment |

ⵔ Space is not required for attachment / detachment |

ⵔ Same as left |

| 7 | Vibration Ressistance | ᐃ Vibration resistance is supported by additional parts ( Diagram 6 ) |

ⵔ Vibration ressistance is a standard specification |

ⵔ Same as left ( Diagram 7 ) |

| 8 | Material's Hydrogen Resistance | ᐃ Body is Ni, equivalent speficiation SUS316 tube is not supported |

ᐃ Ni equivalent specification not supported |

ⵔ Ni equivalent specification is a standard specification |

Assessment results ⵔ : Excellent ᐃ : Slightly Inferior × : Inferior

◼ Construction

◼ Removability

Download the catalogue or

reach out to us by completing the form.

Hydrogen? Contribution

and Safety Fuel Cell Vehicles (FCV)

and Transport High-Pressure

Products Applications Fujikin's

Achievements